Inventory Management Fundamentals Explained

Wiki Article

The Ultimate Guide To Inventory Management

Table of ContentsSome Known Details About Inventory Management The Best Guide To Inventory ManagementInventory Management Fundamentals ExplainedAll about Inventory ManagementA Biased View of Inventory Management

The periodic supply system is a technique of inventory valuation for financial coverage functions in which a physical count of the stock is done at details periods. This accountancy approach takes supply at the beginning of a period, adds new stock acquisitions during the duration and also subtracts ending inventory to obtain the cost of goods offered (COGS).They can link numerous data indicate the number, including the vendor, product measurements, weight, as well as even variable information, such as the number of are in stock. RFID or radio regularity identification is a system that wirelessly transfers the identification of a product in the form of a distinct identification number to track products and also give detailed item info.

Getting The Inventory Management To Work

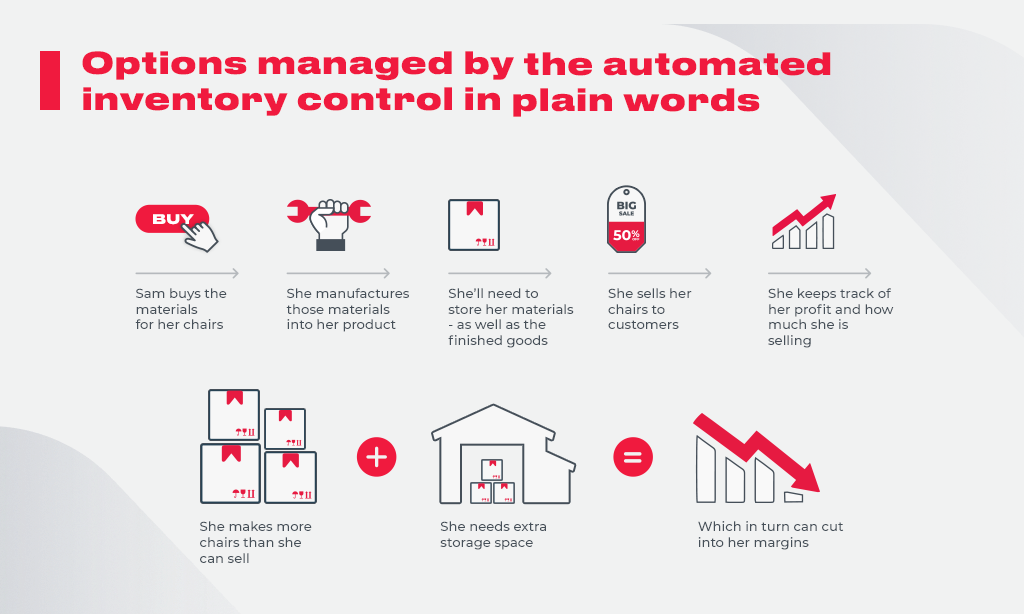

Inventory management refers to the process of keeping, ordering, and also selling of products as well as services. One of the most vital elements of supply management is taking care of the circulation of raw products from their purchase to complete items.An oil depot can store a big supply for a lengthy time. Or for services that sell subject to spoiling items, such as fast-fashion things, going on top of your supply can be extremely costly. One method to represent stock is by organizing it into 4 classifications: first-in-first-out, last-in-first-out, weighted-average, and first-in-first-out.

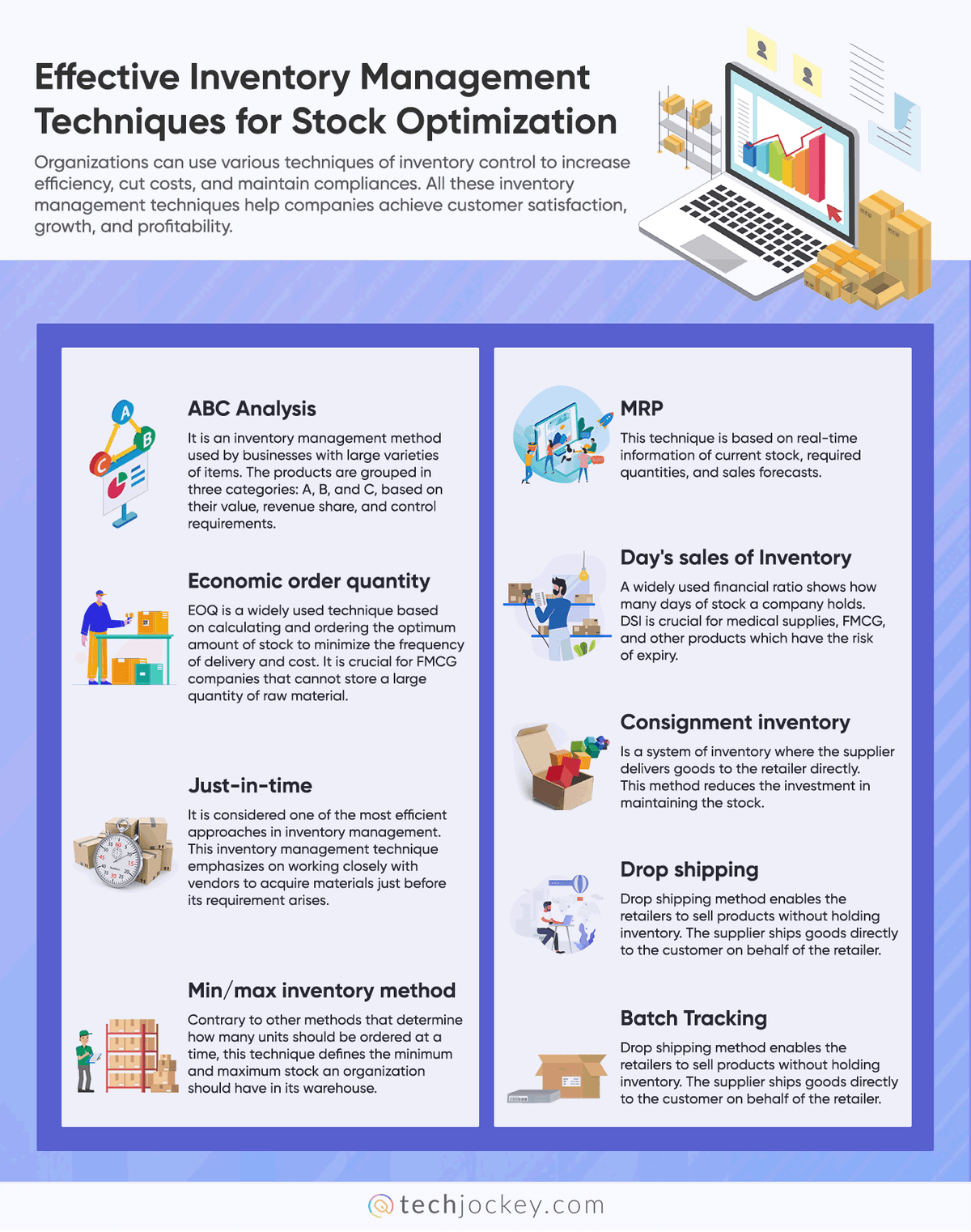

Depending on the kind of firm that it is managing, various supply administration techniques are utilized. Several of these include JIT, material requirement planning, as well as days sales of supply. Other techniques of assessing supply can additionally be made use of depending on national and regional guidelines. The SEC calls for public companies to report the existence of a so-called LIFO reserve.

The smart Trick of Inventory Management That Nobody is Talking About

Discover much more concerning supply administration from Walton University's Supply Chain Administration program's intro on the subject covering everything from forecasting to direct designs: Among the most useful properties of a company is its stock. Inventory Management. In various industries, such as retail, food solutions, and manufacturing, an absence of supply can have detrimental impacts.Having a big stock can also lead to a decrease in sales. Both for small businesses and also large corporations, having a proper inventory management system is extremely essential for any kind of organization.

This is specifically essential for brands wanting to end up being a much more customer-centric company. Stabilizing the threats of overstocks and also shortages is a particularly difficult procedure for business with intricate supply chains. A firm's supply is normally a current asset that it intends to offer within a year. Inventory Management. It has to be gauged as well as counted consistently to be thought about a current possession.

5 Simple Techniques For Inventory Management

Not only will it offer to enhance efficiency, but it's additionally useful for avoiding burglary with the aid of product tracking and safety and security. Supervisors can additionally intend to utilize their supply monitoring plan to keep track of sales treatments which leads to better service.

Providing consumers a number of different kinds of internationally-grown fruit and vegetables in both natural as well as non-organic ranges at a budget-friendly cost, even when the fruits and vegetables aren't in period, is a contemporary wonder many thanks partially to inventory monitoring. Overseeing stock in genuine time as well as also establishing automated replenishment systems is mission-critical to lots of.

The smart Trick of Inventory Management That Nobody is Talking About

6 million plans from their brand name to third-party vendors daily. Their Smart Warehouse uses robotic and also human aid to do the job, but it's supply monitoring that maintains all of it rolling. According to Tech Vision, "Amazon's monitoring strategy, in addition to all that automation, have made the service tremendously lean and suggest by historical requirements." The stock administration of bathroom tissue firms remained in the hot seat in early 2020 as panic-buying brought about shortages across the country.

Here are the primary kinds you should know: Basic material, This describes items my link of your product that requirement to be shipped to you and also put together by your team. Supply systems that track these need to make up provider timelines. Underway, Products made from Recommended Site raw materials as well as are currently being put together or organized loss under this category.

Report this wiki page